Highlights

-

- Robust mechanical structure suitable for high speed

- Welding white and colored profiles

- Mitsubishi PLC control system- 7'' touch screen

- User-friendly Kaban interface with easily adjustable parametric structure

- Software that enables customer-based production

- Heat adjustable according to profile type with PID system

- Heating and welding time adjustable according to profile type- Working with barcode reader

- Automatic lubrication system

|

Description

|

|||||||

| Welding Measures | Profile | Height | 210 | mm | |||

| Profile | Width | 130 | mm | ||||

| Width / Length | Maximum | 2460 / 3575 | mm | ||||

| Width / Length | Minimum | 325 / 410 | mm | ||||

| Welding | Angle | 90 | ° | ||||

| Machine Axes | X Axis | Motor power | 0,75 | kW | |||

| Y Axis | Motor power | 2 x 0,4 | mm | ||||

| Conveyor | Motor power | 2 x 0,37 | kW | ||||

| Technicial Specifications | Air | Pressure | 6-8 | bar | |||

| Air | Total Air Consumption | 61 | l/min | ||||

| Feed | Voltage | 400 | V | ||||

| Feed | Voltage | 10,5 | kW | ||||

| Weight | Net | 1800 | kg | ||||

| Weight | Gross | 2320 | kg | ||||

| Sound | Level | 96 | dB | ||||

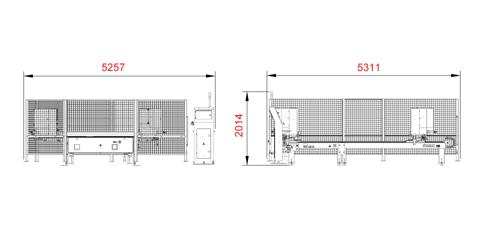

| Machine Dimensions | Length | 5311 | mm | ||||

| Machine Dimensions | Width | 5257 | mm | ||||

| Machine Dimensions | Height | 2014 | mm | ||||

Design

- Mechanical structure that can weld PVC profiles at high speed

and high quality

- Stress relieved cast and welded parts to ensure consistent high speed accuracy

- Teflon replacement system with sliding on the resistance

- Ease of profile feeding

- Working with barcode reader

- Pressure control system

- Stress relieved cast and welded parts to ensure consistent high speed accuracy

- Teflon replacement system with sliding on the resistance

- Ease of profile feeding

- Working with barcode reader

- Pressure control system

Control Panel

- 7'' touch screen

- User-friendly Kaban interface with easily adjustable parametric structure

- Software that enables customer-based production

- Mitsubishi PLC control system

- Heat adjustable according to profile type with PID system

- Heating and welding time adjustable according to profile type

- Working with barcode reader

- Data transfer via memory card

- Memorizes 2000 profile information

- Ethernet connection

- User-friendly Kaban interface with easily adjustable parametric structure

- Software that enables customer-based production

- Mitsubishi PLC control system

- Heat adjustable according to profile type with PID system

- Heating and welding time adjustable according to profile type

- Working with barcode reader

- Data transfer via memory card

- Memorizes 2000 profile information

- Ethernet connection

Welding Unit

- Welding white and colored profiles at 90° angle

- Easy to change welding molds

- Easy profile feed flow

- Top clamps

- Tolerance system

- Easy to change welding molds

- Easy profile feed flow

- Top clamps

- Tolerance system